Our Factory

Quality Control

FSSC22000(International Food Safety Standard)

Certified Factory

(August 2017)

We have established over 1,000 sanitation and quality control standards to maintain a high level of quality for our entire factory, including factory-internal standards, production standards, and sanitation standards.

What is the “FSSC 22000”?

FSSC is an abbreviation for “Food Safety System Certification” and the “FSSC 22000” is a food safety management system for food producers that has been certified by the GFSI (Global Food Safety Initiative). The FSSC 22000 appends additional requirements to the ISO 22000 and ISO/TS22002-1 standards for general sanitation control.

(The requirement of FSSC 22000 is to manage the entire food chain from the manufacture of materials used for manufacturing until the finished products reach customers, and the first priority is that the products that arrive at customers’ hands are “safe and secure” I will.)

Quality Control

FSSC22000

(International Food Safety Standard)

Certified Factory

(August 2017)

We have established over 1,000 sanitation and quality control standards to maintain a high level of quality for our entire factory, including factory-internal standards, production standards, and sanitation standards.

What is the “FSSC 22000”?

FSSC is an abbreviation for “Food Safety System Certification” and the “FSSC 22000” is a food safety management system for food producers that has been certified by the GFSI (Global Food Safety Initiative). The FSSC 22000 appends additional requirements to the ISO 22000 and ISO/TS22002-1 standards for general sanitation control.

(The requirement of FSSC 22000 is to manage the entire food chain from the manufacture of materials used for manufacturing until the finished products reach customers, and the first priority is that the products that arrive at customers’ hands are “safe and secure” I will.)

Our Six Basic Sanitation Control Departments

In order to stably provide products that are of good quality as well as safe and secure, we have implemented inspections in each department through our process of creating a product from raw water, and we have constructed sanitation control regulations, equipment/ an employee operation management system, as well as a sanitation control system.

① Water Quality Inspection

- Daily inspection of raw water by the city, factory quality control department, and external organizations

- Water quality inspections in the factory quality control department

- Storage of inspection data

② Machine Inspection

- Daily inspections and checks of sterilizers, filters, and other machines

- Daily management that includes the adjustment, cleaning, and maintenance of all machines

- Storage of inspection data

③ Production Inspection

- Including product sampling inspection

- Product inspection: Storage of inspection data such as quality inspection, sensory inspection, external inspection organization, etc.

④ Product Inspection

- Product inspection: Product inspection with an image inspection machine (water volume, label, surface stains, etc.)

- Data storage: Inspection data storage, product storage until the expiration date, etc.

⑤ Employee Inspection

- Check inspection of clothing, hairstyles, and other items based on our sanitation standards manual

- Storage of control check data

⑥ Factory Inspection

- Factory entrance and warehouse inspections, sanitation control checks, etc.

- Storage of control check data

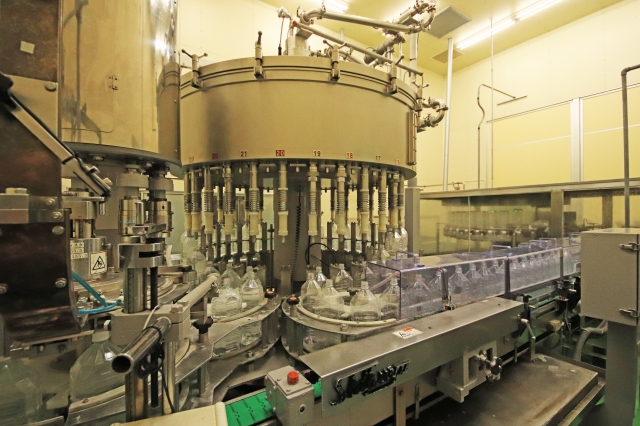

The “Shibushi Water” Production Process

Below, you’ll see how natural spring water from Kirishima becomes “Shibushi Water” mineral water.

First Process

(Raw Water to Filling)

Water Source Area

Water Source Area

Our water source is a Shibushi-city-managed source called Heijo located next to our factory in the Anraku district.

(high inspection standards and operational management)

Heat Sterilization and Filtering

Heat Sterilization and Filtering

For safety, we perform multi-level filtering and then sterilize our water using high heat.

(Heat processing is a quality control standard)

Filling

Filling

After further filtering, the water is filled into bottles while still at a high temperature.

(Only inspected bottles are used, and our products are made with safety measures in place and in a germ-free environment)

Cap Sterilization and Cap Tightening

Cap Sterilization and Cap Tightening

Caps that have been UV sterilized and have had their static electricity removed are used.

(The cap tightening values are also adjusted)

Second Process

(Lay Down Sterilization to Image Inspection)

Lay Down Sterilization

Lay Down Sterilization

After being filled, the bottles are laid down to sterilize the full interior of each container.

(Products are made with lay down sterilization and in a completely germ-free environment)

Cooling

Cooling

After the surface of the bottles have been sterilized, cooling is performed.

(The entire product is sterilized)

Labeling/Printing

Labeling/Printing

Thermal contraction is used to affix labels and to print the expiration date.

(Camera inspections are used to conduct checks)

Image Inspection

Image Inspection

Image inspection is used to conduct a final check, and then product sampling inspections.

(Final product inspections, etc.)

Third Process

(Sealing to Shipping)

Sealing

Sealing

The water is packed into cardboard boxes and weight checks as well as other inspections are performed.

(Final checks per single case, expiration date printing, etc.)

Pallet Loading

Pallet Loading

The water is loaded onto pallets and prepared for shipping.

(Automatic robots are used to accurately load the product)

Shipping and Storage

Shipping and Storage

The water is delivered to our customers throughout Japan.